High temperature heat pumps are a game changer. How about a sub £500 heating bill for the whole winter? Higher temperatures present a new opportunity to store cheap energy in a heat store (a large buffer tank).

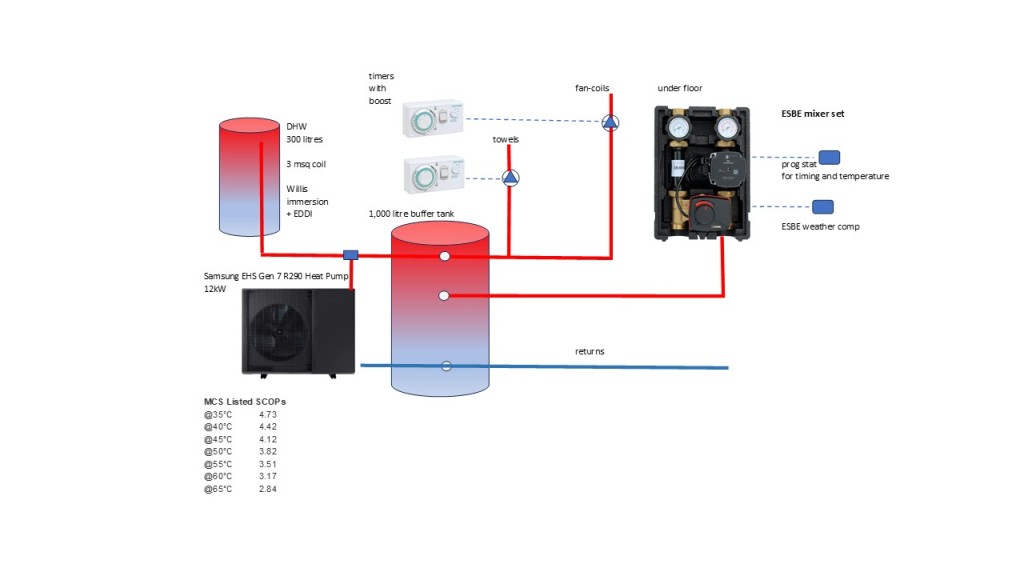

Off-peak electricity costs a third of the day rate allowing heat pump energy multiplication to produce unbelievably low-cost heating (like 2.5p/kW.hr). A heat store can time shift the night rates to the following day with that energy simply dispensed to underfloor heating and fan-coils by blending it back down to the required temperatures. With energy this cheap the inefficiencies of large buffer tanks and blending are hardly relevant.

Large tanks are better for high temperature heat pumps which don’t like short cycling and prefer a large volume of water to chew on so that’s another win.

For example: Over 5 hours a 12kW heat pump can place 60kW.hrs in 1,476 litres of water raised from 30c to 65c. As the model lower down shows, that costs just £300 over 200 days of winter. Similarly,, a 1,000 litre tank, plus a large hot water cylinder and a heated floor slab make a good combination to store this night time bounty ready for the next day.

Cheaper than a battery

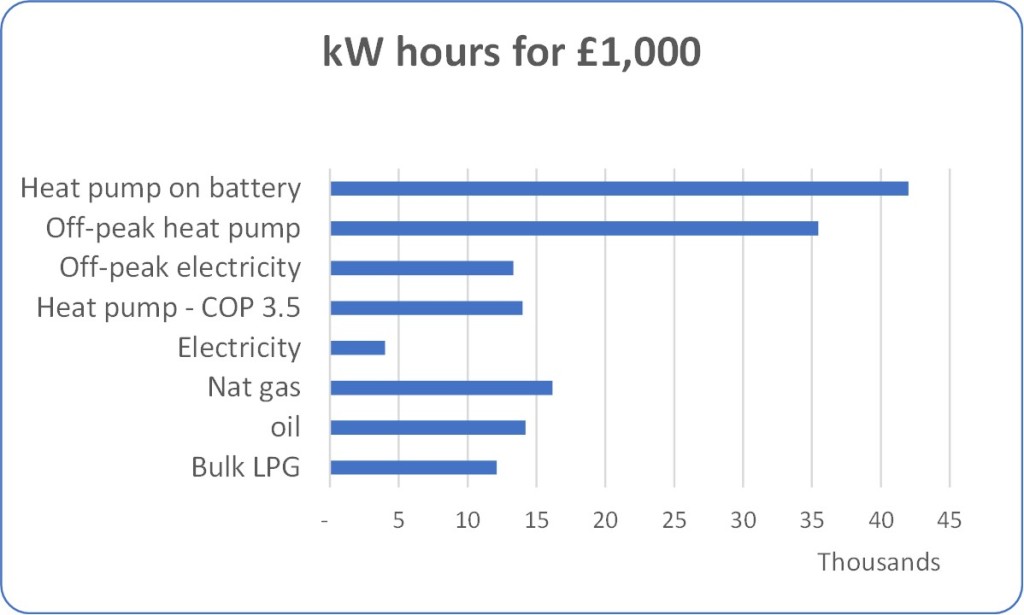

A 1,000 litre tank can store 40kW hours and costs about £1,500. A battery that can make 40kW.hrs (via a heat pump) would cost twice as much and could wear out after 10 years. Water lasts forever so works well as a storage medium; it doesn’t even burst into flames. Having said that, batteries are still very useful and will become strategically important when you access the very large one in your car. The battery is the top performer in the chart below because the heat pump will run a better COP during the day.

N.B The 7.5p off-peak rate is for electric cars but economy 7 is a workable alternative.

A much bigger heat pump

In order to bank the entire heating load over just a few night hours the heat pump will have to be significantly bigger than normal. 12kW is a good place to start especially if only single-phase electricity is available. The Samsung EHS Gen7 R290 12kW is a good example.

Additional power

The calculated heat loss of the house must be matched by the heat pump power (to get the grant) and, on paper, a big heat pump will easily meet that requirement but the stored energy may not always meet the actual demands of the day. Cheap power is time limited rather than power limited.

If there is the occasional shortfall the heat pump is still there to give a powerful boost – at a lower set point to leave the water-battery ‘empty’ as it goes into the night – however there is a better way.

Part of a sensible strategy is to have another smaller heat pump (like a mini-split) that runs mainly free off solar panels. Obviously this helps to keep the electricity costs down but also gives the option of topping up when necessary at minimal cost. The blown air of a mini-split is immensly useful for laundry drying and the cooling feature gets the air-con requirement largely sorted too. Forget the daft headline costs of regular heat pumps – mini-splits can be bought for around£600 and you’d get one fully installed for under £2,000.

Domestic hot water

To store off peak energy the 300 litre domestic hot water cylinder has 3msq coils for heat pump use. It may require a trickle charge during the day and instead of repeatedly firing up the heat pump an EDDI solar diverter tops it up via a Willis remote immersion heater (better for stratification and servicing if you were wondering). The EDDI captures even tiny excesses throughout the day to produce a higher temperature and the lost exports are about equal to the cost of running the heat pump.

System benefits

Water is usually hot enough to make towel rails work properly.

A large domestic hot water cylinder needs fewer daytime top ups if any.

The big heat pump gives faster DHW recovery times (if needed).

Fan-coils take from the hotter level of the heat bank.

Fan-coils can tolerate high temperatures so a boost mode is possible. Eg. 5 mins of full power on startup to give fantastic response times.

Heating can be zoned without complications.

Off-peak electricity is mainly renewable so this system is as green as Kermit.

Daily characteristics

In the morning the tanks will be hot and ready. The bathrooms will be toasty with the towel rails on full pelt. The bedroom fan-coils instantly transform a cold room into a warm one and there’s loads of hot water for showers. Downstairs the floors are already warm.

The towel rails stay on for a while but all else takes a rest until the floor slab downstairs calls for a top up from the big tank. With a bit of sunlight the EDDI starts to reheat the hot water tank and the mini-split might be able to run free.

At this point the big heat pump has not run at all, at any time, during the day. However, by the evening the temperature is getting low in the big tank, the floors can continue to keep warm even with water down to 25c but the fan-coils may need a last-minute boost from the big heat pump. UFH in bathrooms is a good counter to the possible end of day shortfall. Note that this is all fine tuning to avoid costs; if more heat is required then the system can perform just like any other and in fact even better.

Controls

Every thing is much simplified with no interlinking of elements.

The heat pump is allowed windows of operation on a timer and tank thermostats.

The night time set point would be 67C and 45C for the day.

The UFH is timed and controlled by a thermostat with an ESBE mixer if weather compensation is required.

Fan-coils (OriginalTwist DIY units of course) are timed and thermostatically controlled locally.

Simplicity

There are many options to add sophistication to this system; weather compensation, ESBE electronic temperature reducers, DHW via plate heat exchager, blending down for fan-coils, fan-coils boost feature, air source GSHP boosting (as per the OriginalTwist hybrid concept), batteries.

All should be weighed by the PV test: would the money be better spent on more PV panels?

ZERO COST HEATING

As you increase the size of a solar array so the energy bills fall and the export tally rises. For some well insulated houses the income will pay the electricity bills – ZERO COST heating has just become easier.

From the chart below you can work out how many kW.hrs your current system requires over the winter. Just compare each £1,000 bar with your own bills. 25 -30,000 kW.hrs would be normal. Ultra insulated homes nearer to 15,000 and only about a third of the way up a £1,000 bar. Note how the off-peak system is easily twice as good as anything else though don’t compare with direct electric heating unless you want to cry.

Just how cheap for 200 days of winter?

The Original Twist model of this entire system looks something like this:

A 12kW ASHP running for 300 minutes a night charges a 1,000 litre tank, a 300 litre hot water cylinder and the floor slab.

Over 200 days of winter this makes 12,000kW.hrs for £300. No, that’s not a mistake, £300 for 200 days!

The 3kW mini-split adds 1,000 kW.hrs for £125 (half from PV).

Total cost for 13,000 kW.hrs is £425 and less with large PV.

The same energy would cost £500 more with conventional daytime heating.

Could these trivial heating bills be covered by solar exports – maybe.

Ground source heat pump?

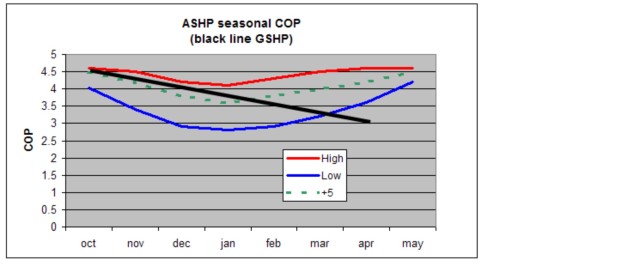

You’ll see on the chart below how night time use of an ASHP (blue line) is particularly disadvantageous compared to a GSHP (black line) which doesn’t really see any significant changes in source temperatures. From that point of view it might seem that this system will be optimised by using a GSHP for the night runs and an ASHP for the day time back up.

Furthermore the GSHP will not suffer the defrosting cycles which will eat up into the precious off-peak time.

Off-peak running of an ASHP roughly halves the heating bill but strangely the GSHP doesn’t gain much because the night rates are so low. Something like £100 a year does not seem worth chasing with a GSHP.

You won’t find an R290 high temperature GSHP either: that’s because they are fitted indoors and spilled R290 is toxic. The 10kW IVT GSHP might scrape in as a contender though.

Conclusion

This idea can be scaled and tweaked to suit individual requirements but the underlying message is convincing.

Off-peak electricity can be time shifted with large amounts of water to dramatically cut heating costs.

A concrete slab also stores heat usefully so a boost at the last hours of off-peak could be part of the mix.

a few times a day.

a few times a day.

Leave a comment