What if Morgan was an assembly only operation? All the tapping, hammering and sewing operations would go and all the components would come from outside.

Here all the oily bits come from a Mazda MX5 giving IRS, the best gearbox and the 2.5 litre Mazda/Ford Duratec engine.

Jenvey 45DCOE replica throttle bodies give the period look to the engine bay and are good for over 250bhp.

The structural bodywork can be even more woody than before. Just quick and accurate.

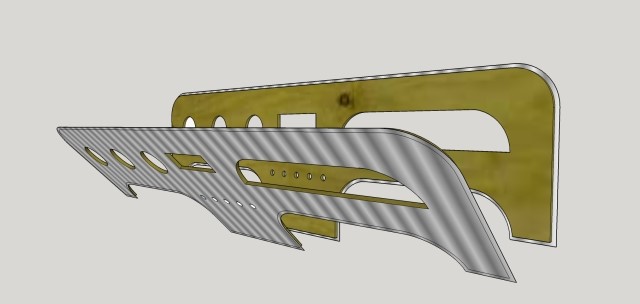

Aircraft grade birch plywood stuck onto an aluminium sheet is CNC machined away to leave internal struts for load distribution and pockets for plug inserts.

Mirror image panels are glued wood-to-wood and the outside aluminium edges peened over to leave a solid looking panel (but largely hollow inside) which will not only look good with complex curves but be very strong and light.

Loads, from components bolted to the panel, are met by plugs inserted into machined pockets so that any through bolts can’t crush the wood structure when tightened. The plugs are fitted in pairs with a larger star washer in between so that the sharp edges crush into the plywood to give even more load transmission.

Being CNC machined, identical complex panels can be produced quickly and with minimal labour cost. What used to take days now takes a few minutes and assembly is quicker because everything fits.

So now a lighter but much stronger and stiffer car is ready to receive the existing wings, bonnet and cowl. A nice pair of Recaro seats are dropped in and it looks exactly like a traditional Morgan.

So, production could be easily quadrupled, labour halved and maybe the price halved too. So, the best driving Morgan so far and at an affordable price.

What’s not to like?